Continental develops sensors to protect EV batteries

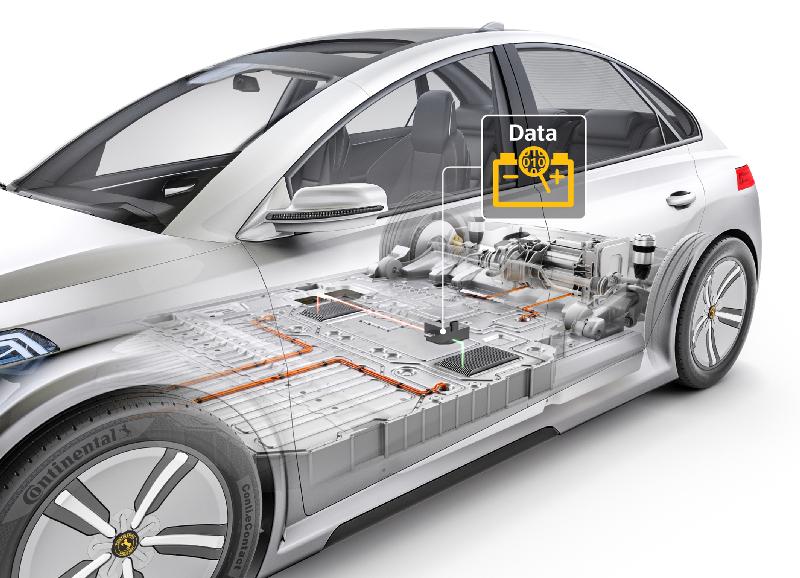

Continental says it is widening its broad sensor portfolio by launching two new sensors for electrified vehicles: the Current Sensor Module (CSM) and the Battery Impact Detection (BID) system. Both new solutions focus on protecting the battery and/or on battery parameter retention.

This year, Continental will begin to manufacture the all-new high-voltage Current Sensor Module (CSM). This compact modular sensor design measures the current and simultaneously detects temperature. Both values are highly relevant as input for the battery management.

The Battery Impact Detection (BID) solution from Continental is also described as a light-weight alternative to heavy underfloor “armoring” against damage.

“Vehicle electrification brings new use cases and thus opens up more opportunities to our sensor activities, because an electric car has all the sensor needs a conventional car has – and more,” says Laurent Fabre, Head of Passive Safety and Sensorics Segment at Continental. “Protecting the battery and retaining its performance, for instance, are two additional tasks in electrified vehicles. The Current Sensor Module and Battery Impact Detection solutions serve both purposes.”

Considering that the battery is the single most expensive component in an electric car, the CSM was not just developed to protect the battery from overcurrents, but it will also help to retain the battery parameters by limiting ageing effects. Integrated either in the battery disconnect unit or in the battery itself, the CSM will provide the two decisive bits of information for battery protection as well as reliable driving range monitoring. To support strict functional safety requirements, the CSM is available as a two-channel sensor, measuring current independently by integrating shunt technology and hall technology in a compact, single unit.

The BID in combination with a lightweight structure detects underfloor impacts and alerts the driver if a stop at a garage is necessary as a result. This relieves the driver of the challenging decision whether an impact at high speed or a low-speed ground contact may have damaged the battery. In comparison to current metal underfloor protection the BID solution can save up to 50 percent of weight, the company claims.

Continental says it is widening its broad sensor portfolio by launching two new sensors for electrified vehicles: the Current Sensor Module (CSM) and the Battery Impact Detection (BID) system. Both new solutions focus on protecting the battery and/or on battery parameter retention.

This year, Continental will begin to manufacture the all-new high-voltage Current Sensor Module (CSM). This compact modular sensor design measures the current and simultaneously detects temperature. Both values are highly relevant as input for the battery management.

The Battery Impact Detection (BID) solution from Continental is also described as a light-weight alternative to heavy underfloor “armoring” against damage.

“Vehicle electrification brings new use cases and thus opens up more opportunities to our sensor activities, because an electric car has all the sensor needs a conventional car has – and more,” says Laurent Fabre, Head of Passive Safety and Sensorics Segment at Continental. “Protecting the battery and retaining its performance, for instance, are two additional tasks in electrified vehicles. The Current Sensor Module and Battery Impact Detection solutions serve both purposes.”

Considering that the battery is the single most expensive component in an electric car, the CSM was not just developed to protect the battery from overcurrents, but it will also help to retain the battery parameters by limiting ageing effects. Integrated either in the battery disconnect unit or in the battery itself, the CSM will provide the two decisive bits of information for battery protection as well as reliable driving range monitoring. To support strict functional safety requirements, the CSM is available as a two-channel sensor, measuring current independently by integrating shunt technology and hall technology in a compact, single unit.

The BID in combination with a lightweight structure detects underfloor impacts and alerts the driver if a stop at a garage is necessary as a result. This relieves the driver of the challenging decision whether an impact at high speed or a low-speed ground contact may have damaged the battery. In comparison to current metal underfloor protection the BID solution can save up to 50 percent of weight, the company claims.