Gold nano-coating works like an anti-fog heating element for glasses

While anti-fog sprays work to a certain extent, warming a glass surface is a better way of keeping it fog-free. A new coating material is designed to do so, and it utilizes light-absorbing gold nanoparticles instead of electricity.

Most of the anti-fog sprays used on things like eyeglasses incorporate hydrophilic (water-attracting) molecules. These draw in and evenly dispense condensation, making it easier to see through. By contrast, your car’s rear window uses integrated elements to heat the glass, keeping condensation from forming in the first place.

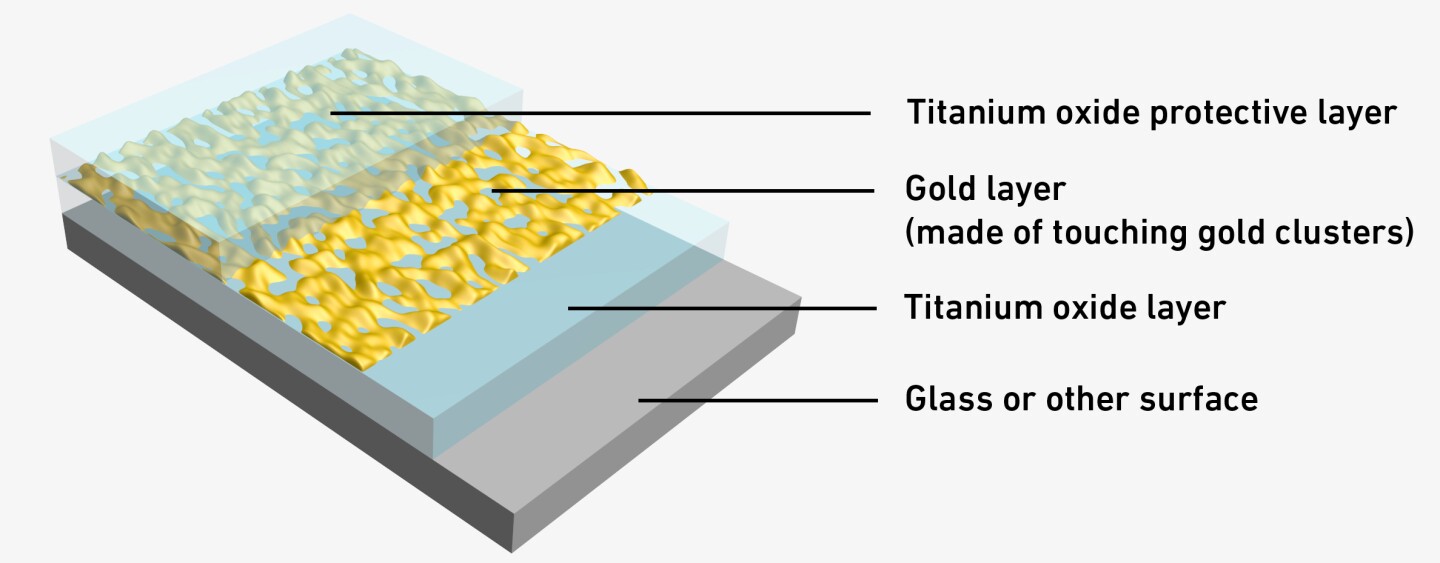

Developed by a team at the ETH Zurich research institute, the new coating likewise uses heat – but it doesn’t require electricity. Instead, it uses a layer of clustered gold nanoparticles, sandwiched between two ultra-thin layers of titanium oxide – the whole coating is just 10 nanometers thick, which is about one twelfth the thickness of a sheet of gold leaf.

The gold nanoparticles absorb much of the infrared spectrum of incoming sunlight, causing the coating to become up to 8 degrees Celsius (14 degrees Fahrenheit) warmer than the ambient temperature. That said, the nanoparticles absorb very little visible light, allowing the coating to stay transparent.

ETH Zurich

The refractive properties of the titanium oxide boost the efficiency of the heating effect. Additionally, the outer layer helps protect the gold from wear and tear.

And as an added bonus, because the gold layer is electrically conductive, a power source such as a battery could be used to heat the coating when direct sunlight isn’t an option.

We first heard about the basis for this technology back in 2019. As compared to the coating which was described at that time, however, this one is much thinner and more flexible. It’s also significantly more transparent, due not only to its thinness but also to the fact that it absorbs infrared light more selectively.

Although very little gold is used in the coating – which helps to keep costs down – the scientists are now looking into other, less expensive metals.

A paper on the research, which is being led by professors Dimos Poulikakos and Thomas Schutzius, was recently published in the journal Nature Nanotechnology.

Source: ETH Zurich

While anti-fog sprays work to a certain extent, warming a glass surface is a better way of keeping it fog-free. A new coating material is designed to do so, and it utilizes light-absorbing gold nanoparticles instead of electricity.

Most of the anti-fog sprays used on things like eyeglasses incorporate hydrophilic (water-attracting) molecules. These draw in and evenly dispense condensation, making it easier to see through. By contrast, your car’s rear window uses integrated elements to heat the glass, keeping condensation from forming in the first place.

Developed by a team at the ETH Zurich research institute, the new coating likewise uses heat – but it doesn’t require electricity. Instead, it uses a layer of clustered gold nanoparticles, sandwiched between two ultra-thin layers of titanium oxide – the whole coating is just 10 nanometers thick, which is about one twelfth the thickness of a sheet of gold leaf.

The gold nanoparticles absorb much of the infrared spectrum of incoming sunlight, causing the coating to become up to 8 degrees Celsius (14 degrees Fahrenheit) warmer than the ambient temperature. That said, the nanoparticles absorb very little visible light, allowing the coating to stay transparent.

ETH Zurich

The refractive properties of the titanium oxide boost the efficiency of the heating effect. Additionally, the outer layer helps protect the gold from wear and tear.

And as an added bonus, because the gold layer is electrically conductive, a power source such as a battery could be used to heat the coating when direct sunlight isn’t an option.

We first heard about the basis for this technology back in 2019. As compared to the coating which was described at that time, however, this one is much thinner and more flexible. It’s also significantly more transparent, due not only to its thinness but also to the fact that it absorbs infrared light more selectively.

Although very little gold is used in the coating – which helps to keep costs down – the scientists are now looking into other, less expensive metals.

A paper on the research, which is being led by professors Dimos Poulikakos and Thomas Schutzius, was recently published in the journal Nature Nanotechnology.

Source: ETH Zurich